Wide range of stainless steel tubes as a response to diverse needs of the market

Industry articles

Welded and seamless tubes

Welded and seamless tubes

Stainless steel tubes - welded and seamless - are the products with a wide range of applications, finding their places both in decorative constructions and very demanding pressure systems.

Application of a properly selected product carries a number of benefits resulting from streamlining the costs and also from long service life of the tubes that are carefully selected to the needs of customers. Wide range of stainless steel tubes offered by Nova Trading allows to choose best integrated solutions.

Welded tubes

The response to diverse demands is a wide range of products commercially available that differ from each other in many ways, also in price. The knowledge of the specifics of installation and product availability allow the customer to select the optimum solution from a wide range of Nova Trading.

Welded tubes, in terms of applications, are divided into two basic groups - tubes for construction and decorative purpose and tubes for pressure application.

The tubes for decorative purpose such as railing production undergo EN10296-2 European standard without the need of carrying additional, more challenging tests. Achieving the right surface quality for a decorative tube requires not only the selection of the right starting material, but no less importantly, professional surface treatment on top quality equipment. Nova Trading sets itself the highest quality standards by offering customers not only polished tubes that are widely used in many modern constructions, but also a product of uncompromising quality manufactured on state-of-the-art service centre equipment and dedicated to customers with the highest quality requirements - these are the SUPER-MIRROR tubes. This product is distinguished by a much lower roughness, which translates into a perfect surface. Decorative use, however, is not only for architecture, but for many more possible applications. One example is the yachting industry, where high weather and seawater resistance is required in addition to the highest surface quality of stainless steel tubes.

The second basic group of welded tubes are installation tubes. In this case, the tightness and pressure resistance of a tube is particularly important, which is achieved by an appropriate production process and confirmed by the tests to which such products are subjected. The production process itself is much slower than the aforementioned structural tubes. The lower speed makes it easier to test the weld seal on the production line, which is a requirement of the EN10217-7 standard. In pressure applications, welded pipes offered by Nova Trading are increasingly becoming an alternative to seamless tubes thanks to the superior product quality from acknowledged producers.

Pressure installations made of welded tubes can be found in industries such as pharmaceutical, chemical, paper, furniture and automotive. In case of the food industry, it is worth mentioning the requirement for smoothness of the internal walls of tubes, to which the answer is the “dairy” tubes in Nova Trading's offer with EN10357 standard.

The tightness of welded installation tubes, also known as process tubes, is usually confirmed by the eddy current test and, for larger tubes, by X-ray testing. The correct choice of diameter and wall thickness for the pressure under which the installation will operate is a task for the engineer, but indicative values can be found in the relevant tables to advise customers on the right choice.

These installation tubes may be subjected to additional treatment to improve their properties for selected applications. The process that improves the anti-corrosion properties of the tube is pickling. This is particularly important for the service life of the installation and for operating costs. Pickling is a process used to remove the discolouration left after welding stainless steel where the chromium content of the steel surface has been reduced. Nova Trading offers customers a wide range of pickled tubes.

An additional process, in this case clearly affecting the mechanical properties of a tube, is annealing. This is particularly important for customers subjecting tubes to the bending process. Annealing consists of heating the material to an appropriate temperature and then cooling it in order to restore the crystalline structure damaged in the welding process.

A rather special case of tubes is “automotive” tubes - intended for the automotive industry. In this respect, the scope of the tests performed often depends on the customer's specific requirements.

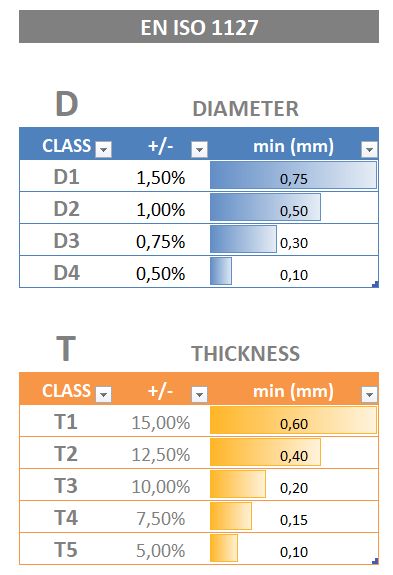

Outlining in a very general way the characteristics of such an interesting product as welded tubes, it is impossible not to mention a very important aspect concerning manufacturing tolerance. Whilst designing any structure or installation we have to remember that the real dimensions of tubes may slightly differ from the nominal dimensions declared in the offer or certificate. The range of possible deviations is defined in the EN ISO 1127 standard divided into several requirement accuracy classes. The following table is best used to illustrate this point:

Clearly, knowledge of welded tubes is quite extensive, and by knowing the needs of customers Nova Trading is able to offer products tailored to these requirements, allowing the company's business partners to save the time and money needed to select the most optimal solution. Nova Trading stocks welded tubes in the range from 6 to 508 mm, including construction and decoration tubes, carrier tubes, food tubess in grades 1.4301 / 1.4307 and 1.4404.

Seamless tubes and hollow bars

In some applications seamless tubes, despite the incredible expansion of welded tubes, are still irreplaceable. Hydraulic systems, heat exchangers, the arms industry or the petrochemical industry are just some of the applications in which seamless tubes are commonly used. The wide range of Nova Trading's offer for this product (range of diameters 6-219,1 mm), the variety of grades (1.4541, 1.4404, 1.4301), manufacturing standards (EN/ASTM/ASME), tolerances in which the tubes were manufactured (precision tubes - EN10305-1, cold-finished - D3/T3 or hot-finished - D2/T2) and tests conducted (test class TC2) allow for satisfying the needs of the most demanding customers.

To meet market expectations, at the special request of customers, Nova Trading offers a rather unique solution – seamless tubes with a refined surface – ground or polished. Such far-reaching surface treatment of seamless tubes is possible thanks to cooperation with selected suppliers offering only the highest quality products, confirmed by recognitions of international certification societies (TUV, DNV, Lloyd's). Meeting the requirements of the European Pressure Directive PED 2014/68/EU and having an ISO management system for production and, importantly, environmental protection, is also a standard requirement from Nova Trading for suppliers around the world.

An excellent complement to the range of seamless tubes are hollow bars, which are an intermediate product between a tube and a bar. They are mainly used in the engineering industry.

Consultation:

Bartosz Kmita – Commercial Director - Long Products, Nova Trading S.A.

Bartosz Kuligowski – Product Manager, Nova Trading S.A.

Please see our offer of stainless steel tubes.