Learn how the self-healing mechanism of stainless steel works.

Discover the role of chromium and the passive layer in providing the highest resistance to corrosion.

Industry articles

Why doesn't stainless steel rust? The self-healing mechanism and the role of the passive layer

How does stainless steel protect itself against corrosion?

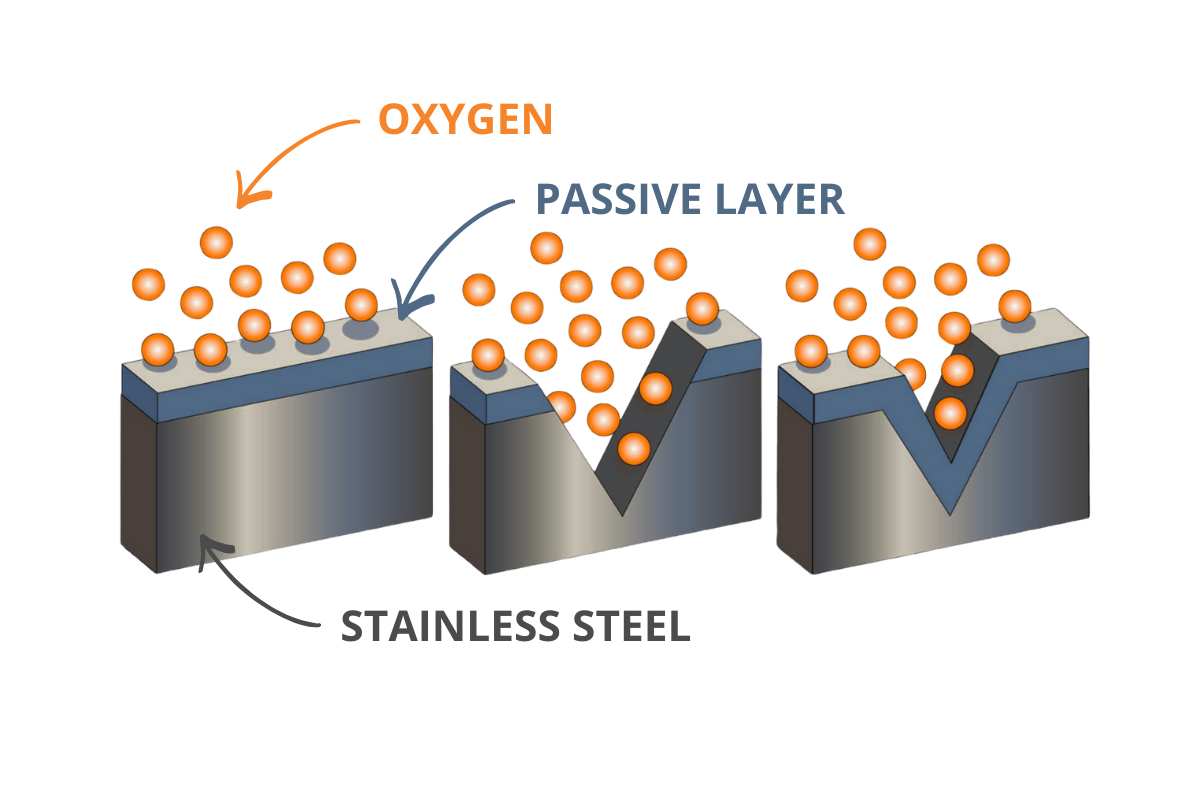

Stainless steel does not rust thanks to the presence of at least 10.5% chromium, which in contact with oxygen forms an invisible, tight and chromium-rich "passive layer" on its surface. A key feature of this layer is its ability to spontaneously rebuild itself (self-healing) in the event of mechanical damage, provided that oxygen from the air or water is available in the environment. Thanks to this, the material does not require additional protective coatings such as paints or varnishes.

Material durability in difficult conditions as a common design challenge

Choosing the right construction material is often a balance between cost and reliability for engineers and designers. In industrial environments, where structures are exposed to mechanical damage, scratches, or aggressive media, traditional anti-corrosion protections (e.g., paint coatings) often fail. Every scratch becomes a focal point for corrosion that quickly degrades the entire element.

This is where stainless steel shows its greatest advantage. Instead of relying on an external barrier, it possesses an "internal" defense mechanism, making it one of the most durable materials available on the market.

Chromium and passive layer properties as a solution to design challenges

The basic definition of stainless steel describes it as an iron alloy containing a minimum of 10.5% chromium and a maximum of 1.2% carbon. These proportions of elements are the foundation of its unique properties.

Protection formation mechanism

🔸reaction with oxygen - the chromium contained in the alloy reacts with oxygen from the environment.

🔸formation of the passive layer - an extremely thin (only a few atomic layers thick) and transparent oxide layer forms on the surface.

🔸tightness - this layer is so compact that it blocks the access of oxygen molecules to deeper iron structures, stopping the oxidation (rusting) process.

Self-healing mechanism - protection that never disappears

An interesting aspect of stainless steel is its ability to regenerate. If the surface is scratched or cut, the "raw" alloy underneath is exposed. In a fraction of a second, the chromium in the newly exposed area reacts with oxygen again, immediately restoring the continuity of the passive layer.

In practice, it looks like this:

🔸in the home environment: A scratched kitchen sink regains full resistance at the site of damage after a short time.

🔸in industry: Machine components subjected to continuous abrasion do not require anti-corrosion maintenance because the passivation process occurs continuously.

🔸in architecture: Building facades maintain their luster for decades, being resistant to atmospheric factors without the need for refreshing protective coatings.

Stability of the passive layer depending on the steel grade - how to make a choice?

In practice, the self-healing mechanism does not work identically for every steel grade. The speed of the passive layer formation and its durability depend on the balance of alloying elements, which determines the application of a given material.

Ferritic steels (e.g. 1.4016 / AISI 430): They mainly contain chromium (16–18%). Their passive layer is stable in moderate conditions, but the lack of nickel makes them less resistant to acids and harder to regenerate in environments with low oxygen levels.

Austenitic steels (e.g. 1.4301 / AISI 304): Thanks to the addition of nickel (approx. 8–10%), the passivation process occurs faster, and the resulting layer is more flexible and resistant to mechanical damage. This is the most universal choice for the food industry.

Acid-resistant steels (e.g. 1.4401 / AISI 316): The addition of molybdenum (2–3%) radically changes the properties of the passive layer, making it resistant to pitting corrosion caused by chlorides. The self-healing mechanism in these steels works effectively even in seawater or swimming pool environments.

Duplex steels (e.g. 1.4462): Thanks to their dual-phase structure and high chromium and molybdenum content, they have an extremely "strong" passive layer that withstands high mechanical stress without the risk of stress corrosion cracking.

You can read more about Duplex steel in the article at this link.

IMPORTANT.

The choice of grade should be dictated by an analysis of the working environment – the more aggressive the media (acids, salts), the more the natural passivation must be supported by appropriate alloying additions.

What is worth remembering?

By choosing stainless steel, you are investing in a material that "takes care of itself". The self-healing mechanism eliminates the need for costly renovations and ensures an aesthetic appearance for years. However, it should be remembered that oxygen access is necessary for this mechanism to function properly – in places where the surface is permanently cut off from air (e.g. under seals in an aggressive environment), crevice corrosion may occur.

Learn more about how to choose the right steel grade for your project:

Discover our offer of stainless steel pipes, profiles, bars and sections